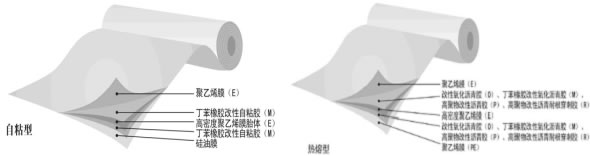

MDS is developed by the ideal waterproofing membrane having a multilayered structure. It uses high-density polyethylene compound tires (E) enhancement layer, supplemented on both sides of the DUWICH patented rubber waterproofing membrane of the surface of the insulating material, polyester film or polyethylene film (E). Ideal as a method for the back under the concrete slab and concrete basement wall waterproofing products, it can be in a narrow place for the box-shaped system provides positive protection.

Size

Width: 1m

Self-adhesive thickness: 2.0mm, 3.0mm

Hot melt thickness: 3.0mm, 4.0mm (where root puncture-resistant membrane to 4.0mm)

Nominal area of 10-15m2

Other sizes are determined by mutual agreement

Product Category

The construction process is divided into two kinds of hot melt (T) and self-adhesive (S).

The hot melt divided according to the ingredients of the modifier the modified asphalt oxide (O), styrene-butadiene rubber modified asphalt oxidation (M), polymer modified asphalt (P), polymer modified asphalt root puncture-resistant(R) waterproof membrane four categories.

Self-adhesive membrane upper and lower surfaces materials are sticking isolation materials, hot melt membrane upper and lower surfaces of the insulating material is a polyethylene film.

Physical Properties

| No. | Project | Implementation of criteria and indicators | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GB 18967-2009 | Q/DW053-2013 | |||||||||

| T | S | S | ||||||||

| O | M | P | R | M | ||||||

| 1 | Tensile properties | Pull/(N/50mm)≥ | Longitudinal | 200 | 400 | 200 | 150 | |||

| Transverse | ||||||||||

| Elongation at break/%≥ | Longitudinal | 120 | 30 | |||||||

| Transverse | ||||||||||

| 2 | Impermeability | 0.4MPa | 0.3MPa | |||||||

| 30min Impermeable | ||||||||||

| 3 | Heat resistance/℃ | 90℃ | 70℃ | |||||||

| Free flowing, no blistering | ||||||||||

| 4 | Low temperature flexibility/℃ | -5 | -10 | -20 | -20 | -20 | -15 | |||

| No cracks | ||||||||||

| 5 | Peel strength/(N/mm)≥ | Membrane and membrane | — | 1.0 | 1.0 | |||||

| Membrane and aluminum | 1.5 | 1.5 | ||||||||

| 6 | Support viscous/min | — | 15 | 20 | ||||||

| 7 | Membrane surface asphalt coating thickness/mm≥ | 1.0 | — | — | ||||||

| 8 | Self-adhesive bitumen peel strength/N/mm ≥ | — | 1.5 | 1.5 | ||||||

Features

The polyethylene reinforcement is characterized by dense impervious, long extension, root puncture-resistant, suitable for planting larger waterproofing and water vapor;

Long extension, can be adapted the settlement deformation greater ease of vibration waterproof construction projects, especially for underground works;

Corrosion resistance, waterproof performance and durability will not be affected, even if the long-term immersion in acidic and alkaline water;

The self-adhesive materials can be 100% of the base surface with waterproof adhesive, to solve leak channeling water worries;

Construction is convenient, simple, easy to operate, pollution-free.

Scope

Waterproof applies to non-exposed construction and infrastructure projects, such as basements, underground buildings, platforms, roof, plaza roof, roof garden, terrace areas such as waterproof, moisture-proof, anti-seepage project; T REE for green roofs andgreen underground buildings.

Suitable for structural deformation, waterproof requires a high level of waterproofing works;

Various buildings roofing, moisture, seepage control.

Construction Methods

Self-adhesive polyethylene fetal membrane using the paste method, pre-paved law, wet-laid method, empty shop law, dry shop construction.

Construction Technology

Melt method: the use of heating tools heating and melting of the membrane underlying bond with the primary coil or coil construction methods. Common tools torch or torch. Construction should pay attention to controlling the flame temperature is not too high, in order to protect the performance of the polyethylene reinforcement base.

Paste method: self-adhesive membrane the roll shop law or the lift shop law is directly attached to the structural grassroots method of construction. Construction, in a dry, flat, no dust on the grass-roots level, first brushing the primary treatment agent, torn off after drying the membrane surface barrier film material pasted directly at the grassroots level, the bond with the primary coil.

Pre-shop law: self-adhesive membrane commonly used in the construction of the basement construction method, also known as anti-paste method. Membrane empty shop at the grassroots, self-adhesive side up, torn off the upper surface of the insulating material, and then pouring the concrete, the concrete sets firmly bonded with 100% of the coil self-adhesive surface, and form a sealed waterproof layer. Construction plane membrane using empty shop law, the facade construction requires the use of mechanical fixation laying.

Wet-Shop: A to grout paste self-adhesive membrane construction methods, to solve the problem of self-adhesive membrane moist basic plane. In the primary smear supporting slurry, the membrane on the surface of the isolation membrane is torn.

Note: When the temperature is low or the detailed structure is appropriate hot-air auxiliary coil is not easy to paste paste.

Packaging & Storage

Package: plastic bags or plastic with a roll into the packaging.

Storage and transport: different types and specifications of products should be stored separately and should not be mixed. Avoid sun and rain, attention to ventilation. The storage temperature should not be higher than 45 ° C, the membrane flat storage put-breaking height of not more than five single-layer stacked stand up storage. Transport to prevent tilt or horizontal pressure, if necessary, covered with tarpaulin.

Shelf life: in normal storage conditions of transport, storage period from the date of one year.