KAS is developed by duwich with high self-adhesive, high-quality, state-of-the-art, cold applied preformed flexible waterproof material.

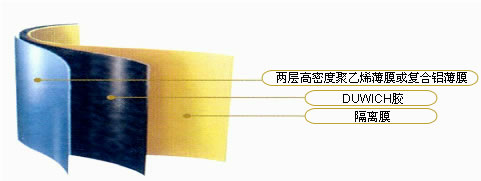

It is composed of two layers of high-density polyethylene film or composite aluminum film surface material to DUWICH patent glue the middle layer, complemented by the isolation material, done special treatment of the self-adhesive waterproofing membrane surface. This high-quality, state-of-the-art thin film after two lamination and chemical bonding, so that all levels tightly bonded together, physical properties than conventional low-density polyethylene have greatly improved. Tear strength, puncture resistance, impact resistance performance have been improved, thus also improve the ability to resist accidental damage.

Product Category

Press on the surface of the material is divided into the high strength polyethylene (PE) film, a polyester film (PET).

By using the function exposed waterproofing works (O) and non-exposed waterproofing works (I).

Product performance is divided into type I and type II.

Size

Width: 1m

Thickness: 1.2mm, 1.5mm, 2.0mm

Nominal Area :15-30m2

Other sizes are determined by mutual agreement

Physical Properties

| No. | Project | Implementation of criteria and indicators | ||||||

|---|---|---|---|---|---|---|---|---|

| GB23441-2009 | GB/23457-2009 | Q/DW051-2013 | ||||||

| PE | PET | The wet Shop Class P | PET | |||||

| I type | I type | II type | I type | I type | ||||

| 1 | Tensile performance | Pull/(N/50mm)≥ | 150 | 150 | 200 | 150 | 150 | |

| Max tensile elongation at/%≥ | 200 | 30 | 30 | — | ||||

| Asphalt elongation at break/%≥ | 250 | 150 | — | 30 | ||||

| Tension phenomenon | The stretching process, the film before breaking asphalt coating of the membrane separation phenomenon | |||||||

| 2 | Shank tear strength/N≥ | 60 | 30 | 40 | — | 30 | ||

| 3 | Tear strength/N≥ | — | 12 | — | ||||

| 4 | Heat resistance | 70℃ Slide does not exceed2mm | ||||||

| 5 | Low temperature flexibility/℃ | -20 | -20 | -30 | -15 | -15 | ||

| No cracks | ||||||||

| 6 | Impermeability | 0.2MPa | 0.3MPa | 0.2MPa | ||||

| 120min Impermeable | 30min Impermeable | |||||||

| 7 | Peel strength/ (N/mm)≥ | Membrane and membrane | 1.0 | — | Membrane and cement mortar | |||

| Membrane and aluminum | 1.5 | — | 1.5 or adhesive surface fracture | |||||

| 8 | Permeability / number of≤ | 2 | ||||||

| 9 | Support viscous/min≥ | 20 | 15 | 15 | ||||

Features

Superior bond strength, with the primary coil integration after lap, lap shear and peel strength greater than their own strength, long life.

Super water lock function, self-adhesive, with the primary coil tightly paste, post-construction caused membrane damage caused by leakage will also be locked at a local scale, to avoid waterproof layer as a whole channeling water leakage.

Excellent self-healing capabilities, sheet rubber elasticity and superior self-adhesive, nails and other sharp objects wrapped cover, self-healing membrane construction expose small sand and other hard objects.

High tensile strength and greater elongation, the grass-roots stretching or cracking, deformation adaptability.

Cold construction, safety and environmental protection: the construction is simple, there is no on-site fire operations, gum and cement-based binder not contain solvents, throughout the construction process to eliminate potential hazards to the environment, but also saves energy.

Scope

On the surface of the material for the self-adhesive web of the high strength polyethylene film layer in the non-exposed the various roofing or waterproofing of underground works, also applies to the drains, sinks, kitchen and waterproof layer. Is especially suitable for waterproofing works are not allowed to use of fire.

On the surface of the material for the aluminized polyester membrane applied to various exposed roofing layer.

Packaging & Storage

Package: plastic bags or plastic with a roll into the packaging.

Storage and transport: different types and specifications of products should be stored separately and should not be mixed. Avoid sun and rain, attention to ventilation. The storage temperature should not be higher than 45 ° C, the membrane flat storage put-breaking height of not more than five single-layer stacked stand up storage. Transport to prevent tilt or horizontal pressure, if necessary, covered with tarpaulin.

Shelf life: in normal storage conditions of transport, storage period from the date of one year.

Construction Methods

Can be used in accordance with the actual requirements of the project, wet-laid, pre-shop anti-stick, empty shops, dry shop and other construction methods.

Construction Points

Make sure that the concrete foundation or a concrete pad surface ice, frost or condensation.The structure of the surface is smooth, no sharp protrusions. Horizontal and vertical planes should be neat, no ice, frost or condensation. The structure of the surface is smooth, no sharp protrusions.

Primer: construction with a brush or roller, per liter of base oil can be coated with 12-15 square meters, depending on the porosity of the surface. The primer surface should be allowed to fully dry before laying KAS. Masonry should be embedded flat or plaster, smooth surface so that the primer.

In the vertical plane, KAS pavement work needs to be suspended, should be set lath fixed waterproof membrane to prevent slipping. Continue with the work, you should remove the lath and re comprehensive laying a layer Kas.

KAS laying peel off the insulation film, and the sticky side of the paving to the primer surface after paving roller rolling surface to ensure good initial adhesion, can be squeezed to remove the air bubbles. Adjacent coils should be aligned, alignment, side seams and at least 50 mm overlap, overlap roller compaction force to ensure complete bonding between the membrane and continuous.

Reinforcing strip before the laying of 300 mm in the horizontal and vertical facade around the corner KAS, you need to make a chamfer with a waterproof coating or other suitable method and aligned Straightening adjacent membrane side lap of at least 60 mm, the short side lapat least 150 mm, roller compaction.

After laying in KAS and check, should pay attention to water damaged parts due to damage caused by subsequent operations, if any, should be clean and larger than the damaged area of the KAS repair and compaction; such damage should as soon as possible moisturizing board or other protective materialcovered from exposure and physical damage.

The backfill material should be compacted layer by layer, to prevent subsidence and drag passed to the waterproofing system.

Note: When the temperature is low or the detailed structure is appropriate hot-air auxiliary coil is not easy to paste paste.