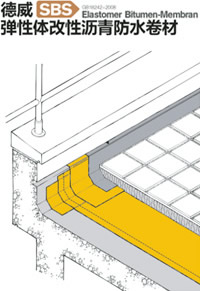

SBS is a styrene - butadiene - styrene (SBS) thermoplastic elastomer as modifier of asphalt impregnated and coated cover material, the upper surface of the cover material or an aluminum foil of a polyethylene film, fine sand, mineral tablets (tablets)made of insulating material such as copper foil can be curled sheet waterproofing membrane.

Application

Basement

Underground buildings

Platform

Roofing

Square floor / roof flower / terrace

Tunnels, airports

Civil air defense projects

Parking lot

Swimming pool

Advantage

SBS elastomer modified bitumen membrane, this membrane has good resistance to high temperature, can be used in the temperature range of -25 to +100 ° C degrees, high flexibility and fatigue resistance, strongpuncture-resistant, tear-resistant capability. Suitable for cold regions, as well as large deformation and vibration waterproof industrial and civil engineering.

Construction

The before construction clean-up grassroots defects, the moisture content of not more than 9%, special brushing base oil and dried thoroughly after the construction. The specific construction as well as the detailed structure should be carried out in accordance with the waterproof design of the project, acceptance criteria and construction specifications.

Basic requirements dry, smooth, clean, no dust, no debris, no oil, no moss spot any hole, hole, crack use cement mortar infill prominent part to chipping.

The headwind brushing primary treatment agent.

The adhesive coated surface of the substrate and the membrane surface, and set aside lap while brushing seam glue.

Stones roll and exhaust compaction.

Lap joint paste.

Manufactured in a factory with manual brushing material, the thickness of the membrane is consistent factors from construction geographically dispersed, highly flexible, it can easily compensate for the shrinkage cracks in the concrete and can withstandtypes of slight deformation of the structure within the service life.

Installation

In the vertical plane, pavement KDS work needs to be suspended, should be set lath fixed waterproof membrane to prevent slipping. Continue with the work, you should remove the lath and re comprehensive laying a layer KDS.

When laying the KDS, peel off the protective paper behind the sticky side of the paving to the primer surface, The paving should brush the surface of the laminated film to ensure good initial adhesion can be squeezed to remove the air bubbles. Adjacent waterproof membrane should be aligned, alignment, side seams and at least 50 mm overlap, the compaction with KDS drum force, to ensure that the waterproof membrane between the fully bonded and continuous, broken parts should be clean, and waterproof membrane is larger than the damaged area to be repaired and compacted.

The backfill material should be compacted layer by layer, to prevent subsidence and drag passed to the waterproofing system.

Physical Properties

| Project | Performance Indicator | ||

|---|---|---|---|

| Ⅰ Type | Ⅱ Type | ||

| Thickness, mm | 3 | 3 | |

| 4 | 4 | ||

| 5 | 5 | ||

| Tensile properties | Pull(N/50㎜)≥ | 500 | 800 |

| Max tensile elongation at%≥ | 30 | 40 | |

| Heat resistance,℃ | 90 | 105 | |

| Low temperature flexibility℃ | -20 | -25 | |

| Impermeability,MPa 30min | 0.3 | 0.3 | |

Availability

| Project | Parameter index |

|---|---|

| Width | 1m |

| Thickness | 3.0 mm, 4.0 mm, 5.0 mm |

| Length | 7.5-10㎡ |

| Store | Should be stored in a dry and ventilated environment, to avoid a temperature of 40 long-term preservation |

*Other sizes are determined by mutual agreement

Quality Assurance

Waterproof Technology Co., Ltd. in Suzhou City, an ideal SBS elastomer modified bitumen membrane manufacturer. Passed the ISO9001 quality management system certification, ISO14001 environmental management system certification.

Technical Services

Working drawings for projects and technical advice to help, please contact the duwich technical services.